Vias technologies

Vias technologies

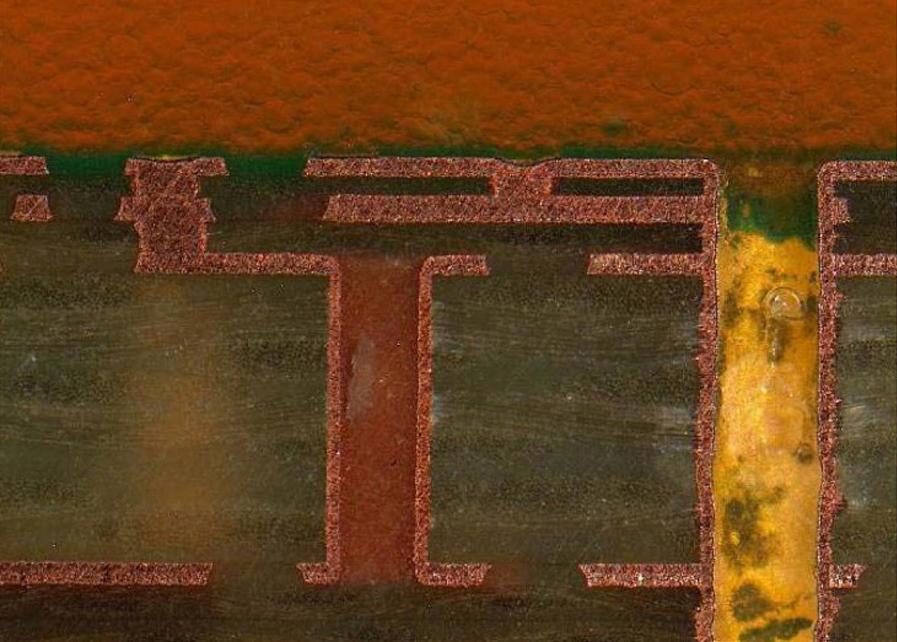

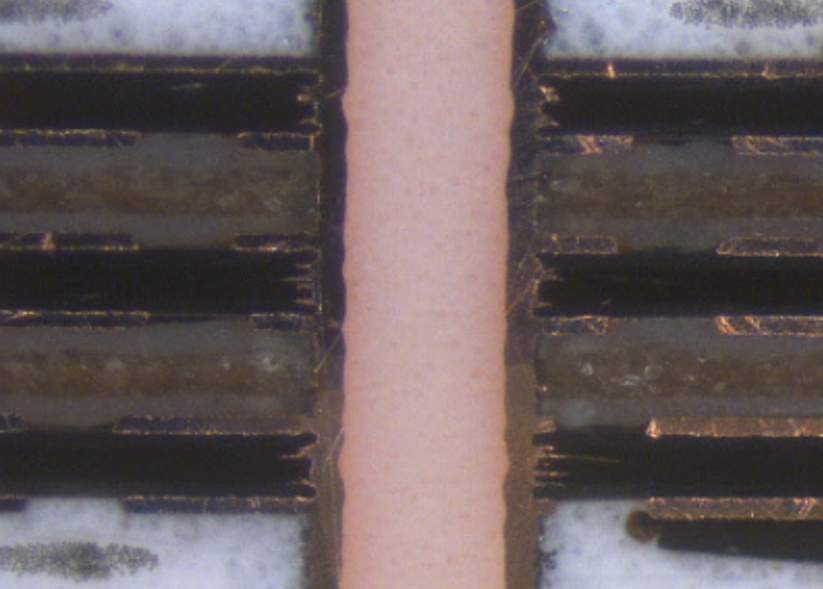

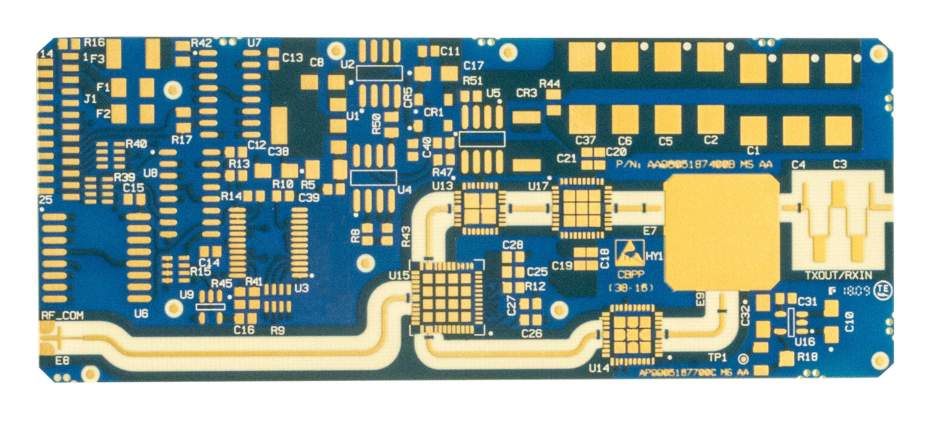

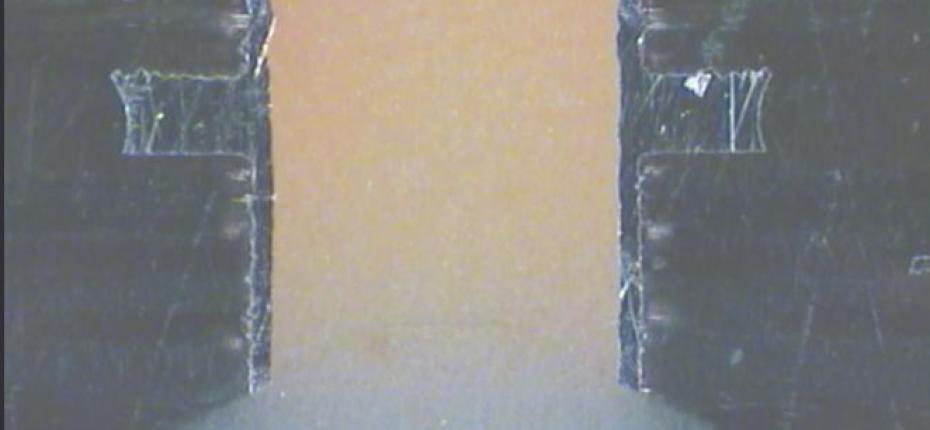

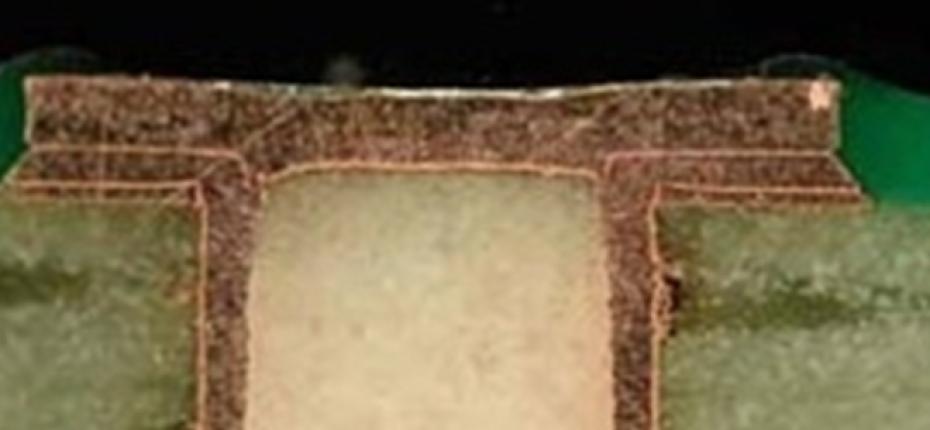

Drilling and subsequent copper plating of the via walls allows different layers of the PCB to be interconnected.

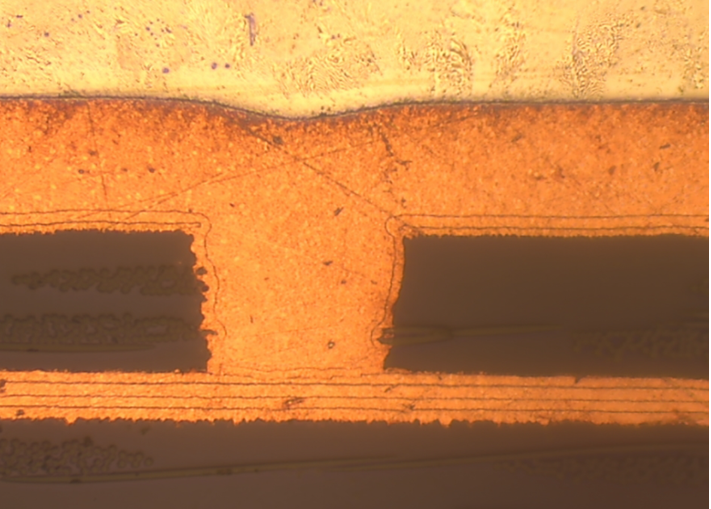

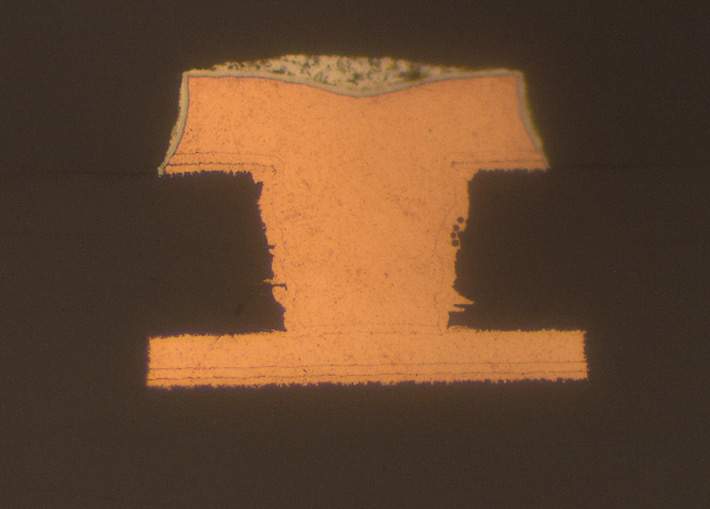

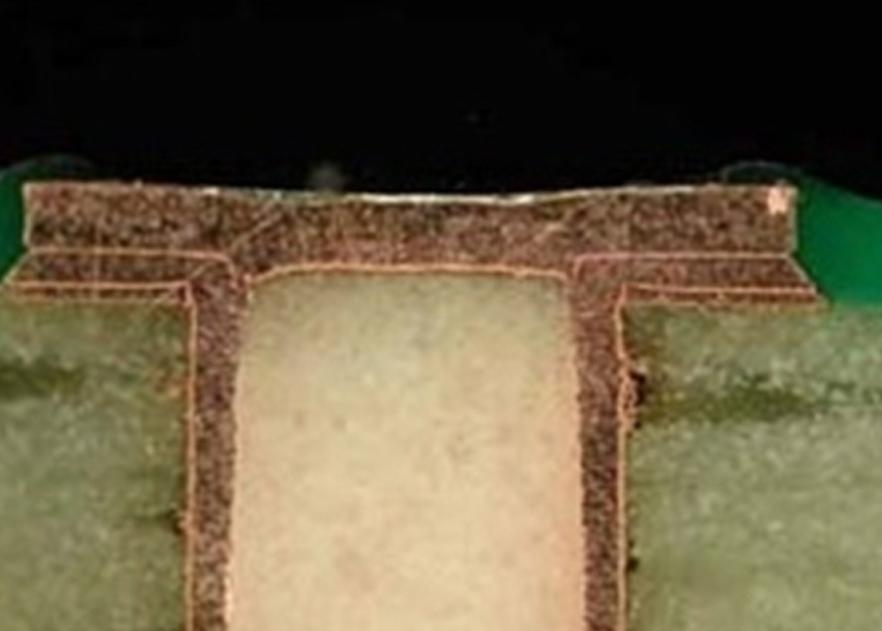

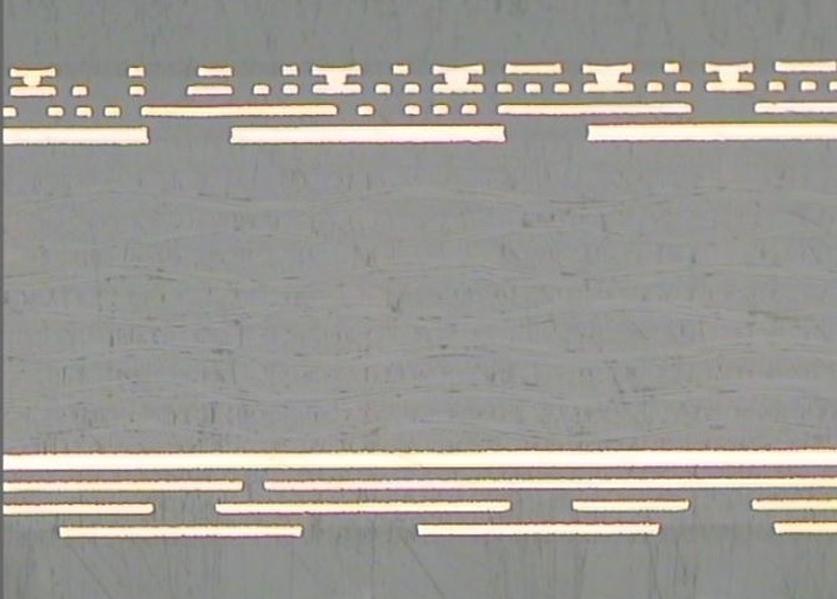

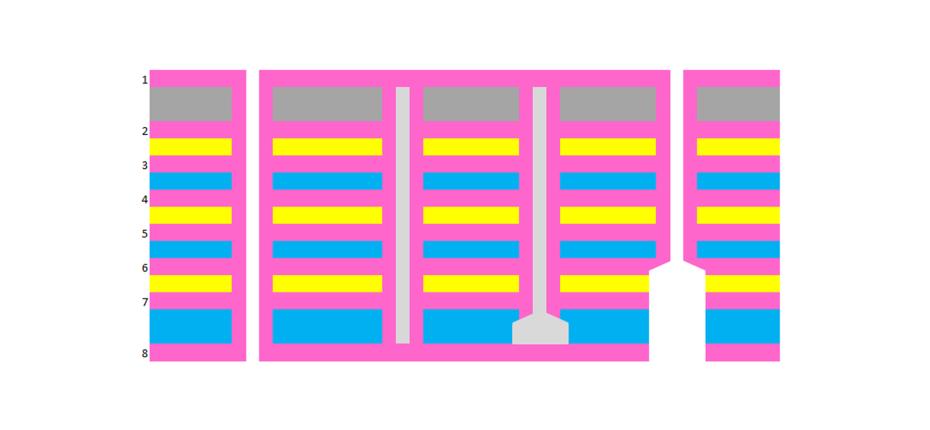

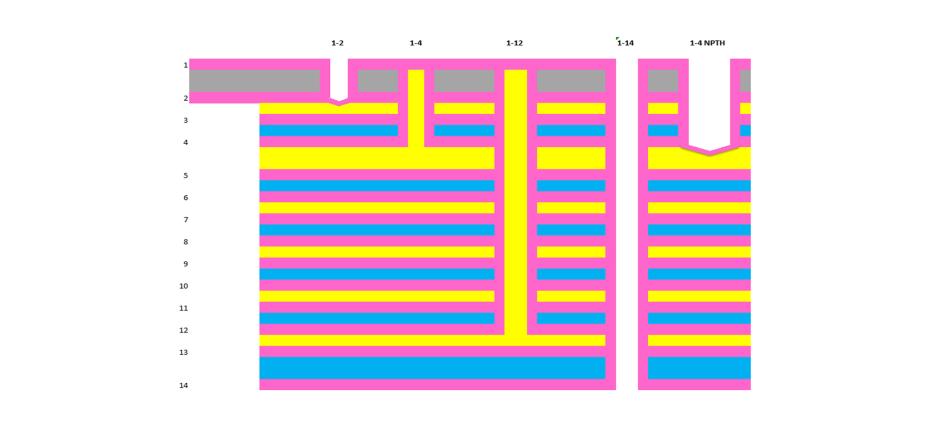

With increasing performance, there is an increasing number of interconnections to achieve, for which it is increasingly necessary to design PCBs with blind vias, obtained by laser drilling or mechanical drilling, or buried or with a combination of both these drilling solutions.

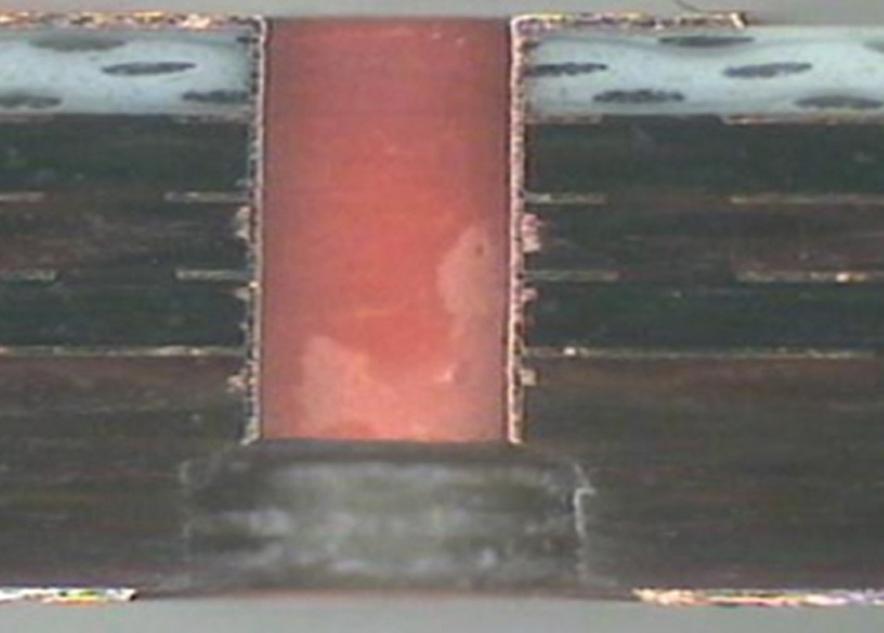

At the same time, we are witnessing the evolution of via filling techniques associated with these drilling processes, including copper filling and resin filling, using conductive or non-conductive resins, with and without vacuum application.

The demand for these drilling techniques and the related filling process is growing rapidly as it responds to the need to produce ever higher-performing electronic devices, including PCBs.

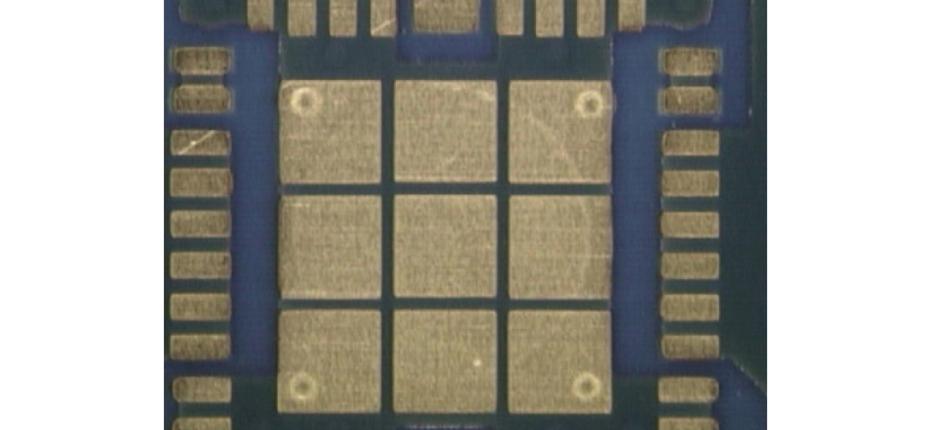

This is the case of the HDI PCB.

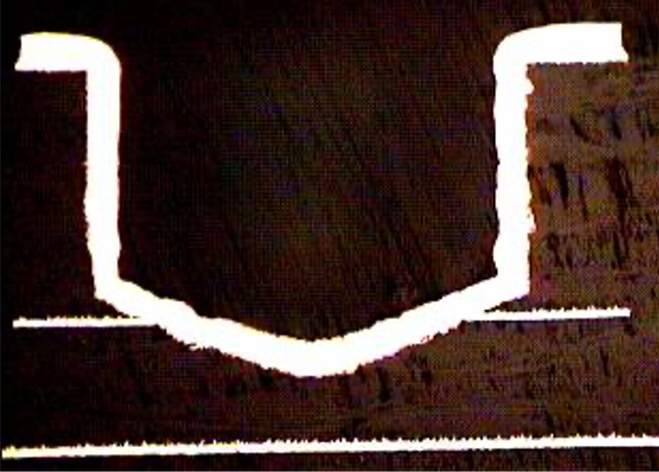

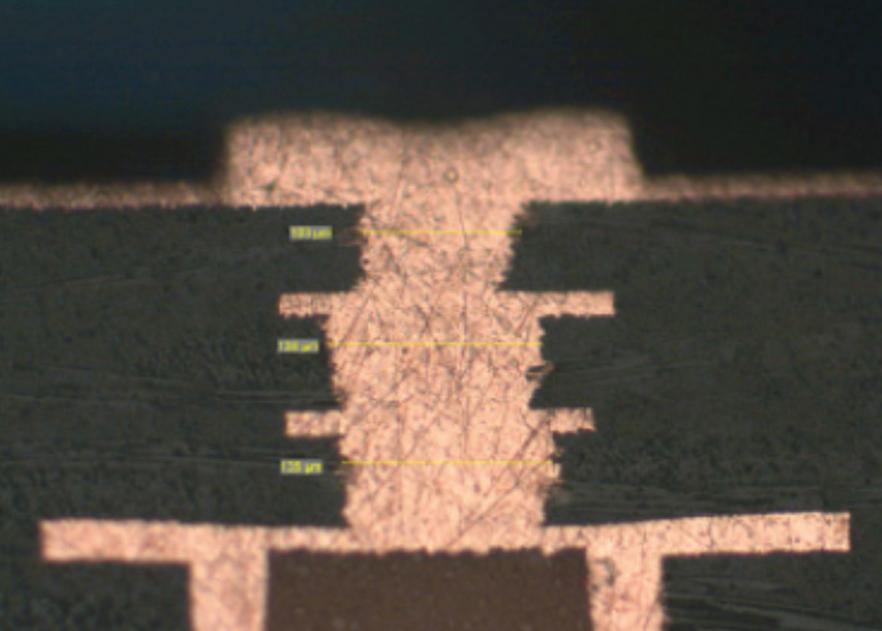

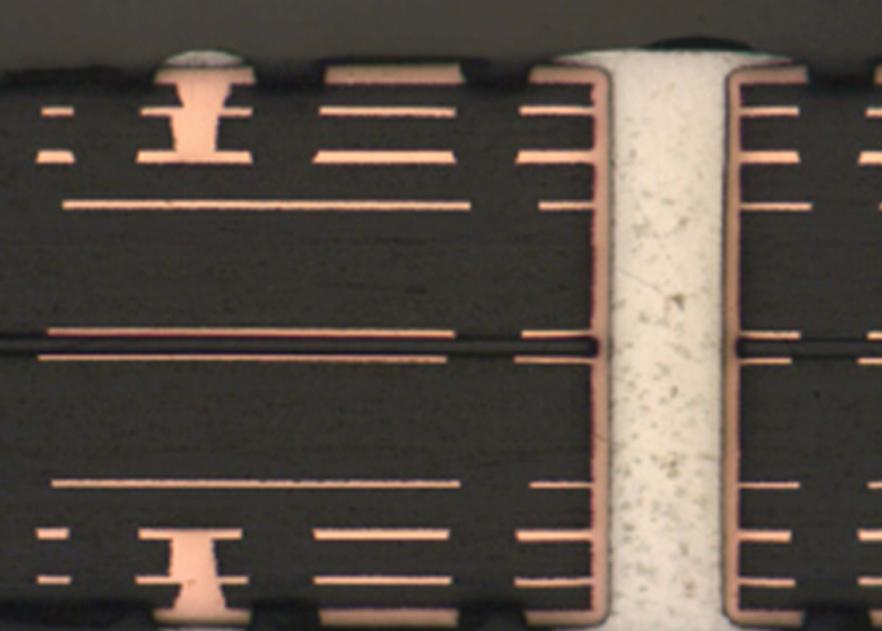

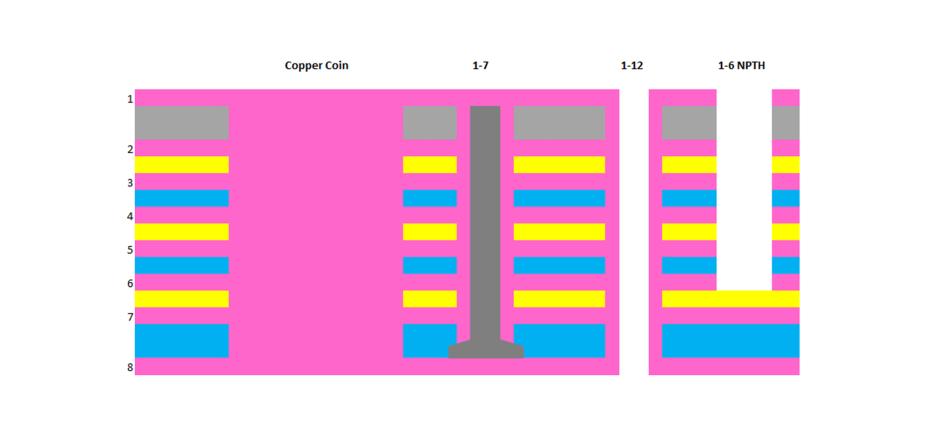

Here the microvias can be a via-in-pad type for mounting components, staggered or stacked, subsequently filled with non-conductive resins - resin filling - and plated with copper at the top or filled with copper - copper filling - and plated with copper to obtain filled and capped vias.

Reverse build-up technology can also be used to ensure that the pads are perfectly level.

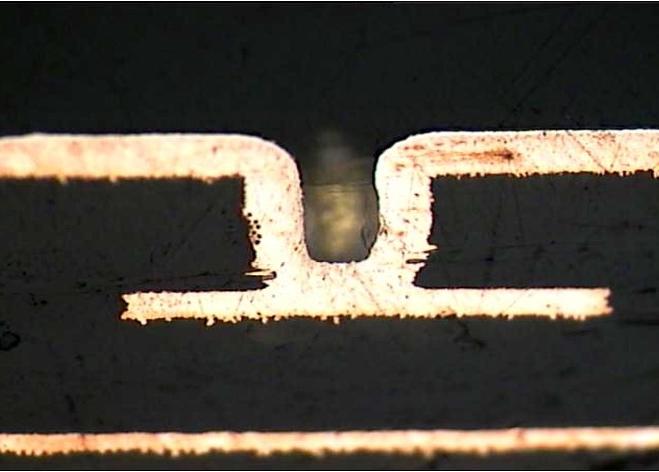

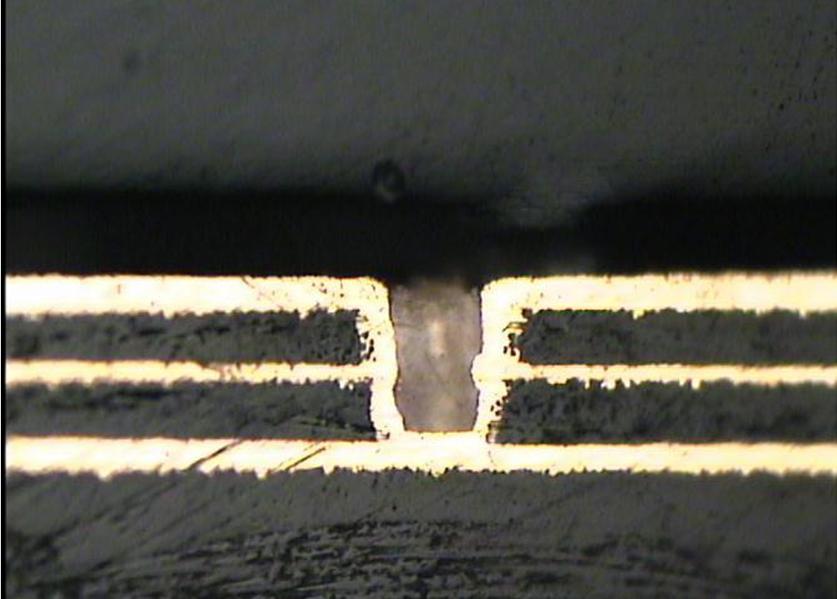

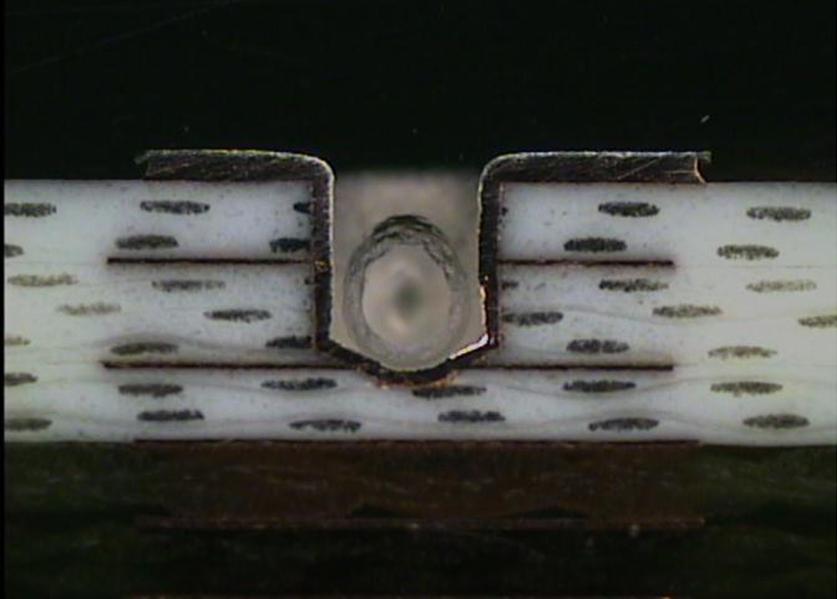

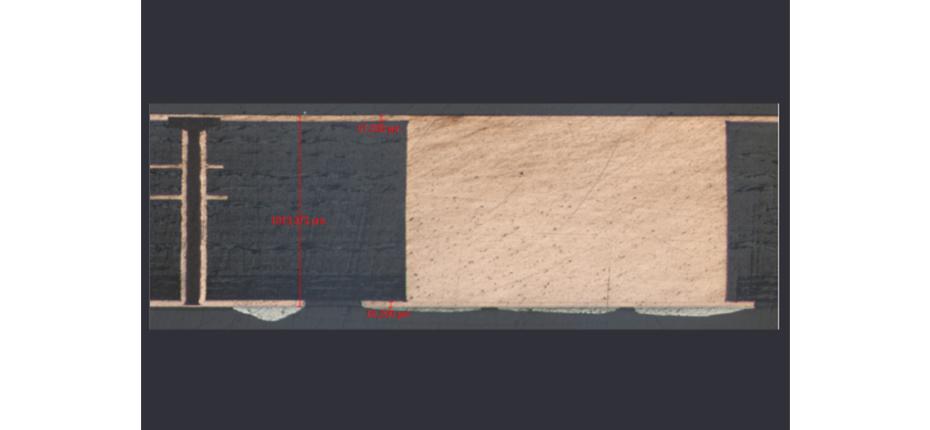

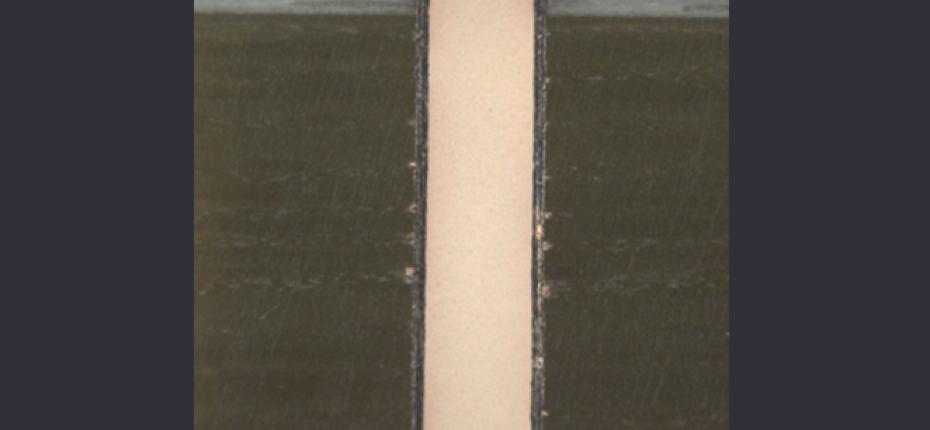

Where the effects of signal interference need to be minimised, along through holes, the back drilling technique can be used for these vias, which removes the unnecessary portion of copper plating.

We have the experience and tools required to handle all the drilling techniques used in PCB fabrication.

Here are some examples.

Rely on us to find the right solution for your PCB.

Contact us for more information

CASE